SOLAL® knows that an increasing number of people are adopting holistic wellness lifestyles and seeking alternative solutions that go beyond what conventional pharmaceutical medicines can offer. Our consumers want products that provide real health solutions, not merely to manage or treat symptoms of diseases.

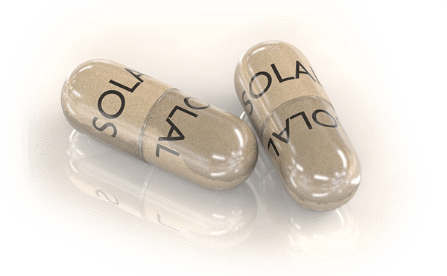

SOLAL®’s range of mind and body nutraceuticals provide synergistic combinations of micronutrients and concentrated plant extracts, at therapeutically high doses, for optimum effectiveness.

SOLAL® also offers an award-winning topical skincare range to complement the skin nutraceuticals. The vision? For every SOLAL® user to experience true wellness because good health is the ultimate wealth.

Mind. Body. SOLAL®

OUR PRODUCTS ARE MANUFACTURED USING:

The SOLAL® range is unique: Many of our products are not available through any competitor brand. Independent research conducted in 2011 shows that the SOLAL® brand is widely prescribed by medical doctors and recommended by pharmacists. SOLAL® products are manufactured using effective doses of the highest quality pharmaceutical grade, active nutritional ingredients and plant extracts, sourced from trusted raw material suppliers. Every batch of raw material is tested to ensure quality, purity and consistency. All of our health and wellness supplements are manufactured in cGMP (current Good Manufacturing Practice) licensed facilities and developed using the latest scientific evidence available. SOLAL® is able to provide medical research to back up any claims that are made.

QualiSafe is a 10-step quality checking and auditing process, that ensures stability, composition and strength from raw material selection and testing, to final product quality and effectiveness. QualiSafe ensures that it is what’s inside the capsule that sets us apart.

1. EFFECTIVE PRODUCTS: Pharmacological screening of ingredients to ensure products are effective.

2. APPROVED: Supplier approval based on a strict vendor approval process.

3. TESTED: Identification tests performed on all raw materials on delivery.

4. VERIFIED: Heavy metals and microbial verification.

5. QUALITY: All products are manufactured in licensed pharmaceutical facilities, under cGMP.

6. ACCURACY: Pharmacist supervision during every step of the manufacturing process.

7. STABILITY: Stability testing to ensure freshness throughout shelf life.

8. NO UNHEALTHY INGREDIENTS: Including fillers, additives or bulking agents.

9. ANIMAL AWARE: Avoidance of animal-derived material whenever possible (e.g. vegetarian capsule shell, not cow or pig gelatin).

10. BATCH TRACEABILITY: Every batch of raw material can be traced to every individual final product.

It’s what’s inside that sets us apart.